GREENHOUSE COOLING SYSTEM:

1.- PASSIVE (WITHOUT COMPRESSOR) COOLING SYSTEMS.

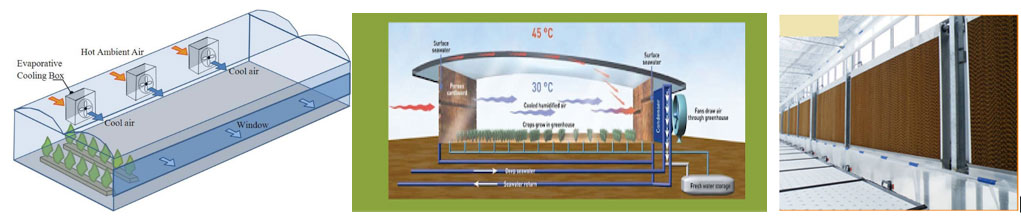

1.1.-EVAPORATIVE COOLING SYSTEM/COOLING PATTERN-FAN SYSTEM.

Indoor temperatures in greenhouse facilities are 18-27 °C under ideal conditions. These temperatures are the temperature range that most plants like best. Under these conditions, plants grow and yield much better.

Humidity conditions are between 60% and 80%.

After the outdoor temperatures rise above 30 °C in summer, plant growth slows down and the product yield of the plant decreases in kg/m2. Especially after 40 ° C, the development of the plant stops completely. In order to prevent this situation, it is necessary to install cooling systems in greenhouses, especially in regions with external temperatures of 30 °C and above.

The fan-pad system is one of them.

Features of Evaporative Cooling Cores.

When it comes to evaporative cooling, the product that expresses the most efficient and economical cooling is evaporative cooling pads. The raw material of the cooling pads is a special kind of paper. The feature of the paper is that it does not lose its rigid structure despite tearing, breaking and getting wet, thanks to the fact that it consists of pure cellulose and is adhered with an adhesive that is not affected by water at the points where the resin impregnated with its own special recipes and the wavy grooves come into contact with each other at opposite angles. The water absorbency of the honeycomb is at the maximum level. It brings air and water in contact with each other at the maximum level. The resistance it creates to the air passing through it is in relative values. The effect of the counter resistance on the fan is very important. Because the flow rate of the fan used in the system may be high, but if the static pressure is low, the air flow to be transmitted can easily decrease.

General way of working of the system:

Soft water is fed from the main system to these evaporative cooler cores, which are mostly placed on the lateral walls according to the cooling need in greenhouses. The honeycombs that hold the incoming water in their body cool the air by evaporation of the water in their body when the hot air flow passes over them and the cool air is sent into the greenhouse by fans. The system is much more efficient in dry climates.

The system works in areas with high outdoor humidity in summer, but its operating efficiency is low.

With the Fan-Pad system, temperatures can be reduced between 8-18 °C.

General design values:

Generally 20 m2 to 30 m2 greenhouse area is required for 1 m2 honeycomb.

In general, the height of the pegs is between 1.5 m and 2 m.

Honeycomb thicknesses are between 10 cm and 15 cm.

The distance between the fans is between 6 meters and 9 meters.

The distance between the fan and the honeycomb is 45 meters. Extending the distance will not provide sufficient cooling as it will reduce the pulling effect of the fan.

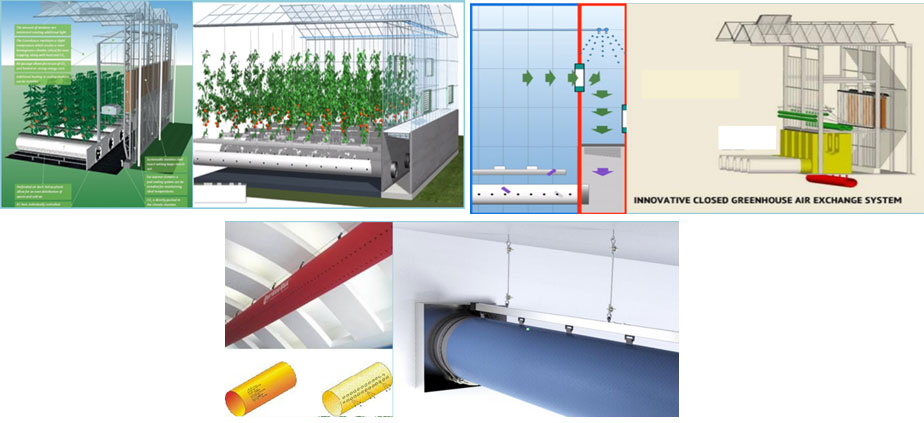

Evaporative Cooling - Ventilation System.

It is a system in which the air conditioned in the Cooler Cores is distributed into the greenhouse with Plastic Air ducts and provides much more ideal air distribution and temperature distribution.

By using dampers with servomotors in the system, the ventilation rate in the greenhouse and the CO2 rate can be controlled at desired sensitivities. It is a versatile system that provides free cooling and ventilation, especially in spring, summer and autumn periods.

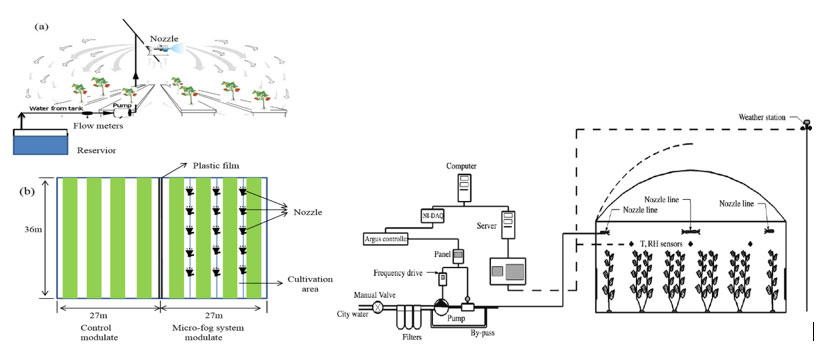

1.2 FOG SYSTEM.

Both evaporative cooling and fogging system are passive cooling systems. Both are based on the principle that water cools the air by taking heat from the air as it evaporates.

Approximately 600 kcal/h of heat energy is needed to evaporate 1 kg of water.

When this heat is taken from the air, the air is cooled.

In fogging, the water is divided into very small particles at high pressure and sent to the greenhouse. The pressure of the water is between 70-120 bar.

The fogging system is also a system that works with much higher efficiency in dry climates. Especially in regions with low wet bulb temperature, it allows the greenhouse to be cooled without the need for active cooling.

Fogging Pumps are high pressure pumps.

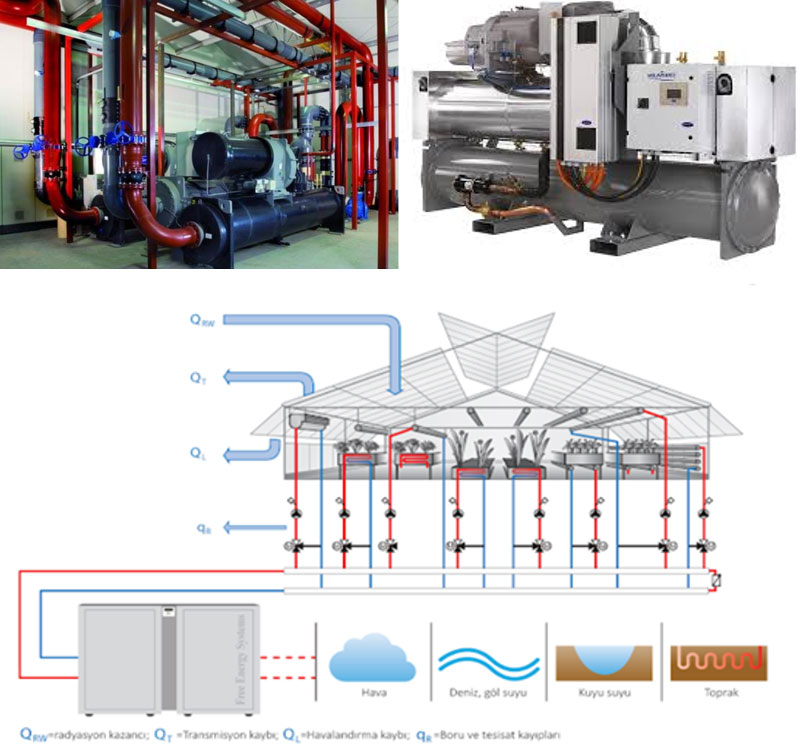

2.- ACTIVE COOLING (COOLING WITH COMPRESSOR) SYSTEM.

2.1.- COOLING GROUP .

2.1.1.-Air Cooled Cooling Units.

Technicial Specifications.

Condensers are air-cooled devices.

Capacity ranges: Between 10 kW and 2000 kW.

Compressors: Scroll Type, Piston Type, Screw Type, Centrifugal Type.

Capacity Control: There are gradual and stepless Proportional Type Capacity Control.

Seasonal yield values: Between 300% and 460%.

Outdoor operating temperature ranges: -18 °C to -55 °C.

Leaving Water Temperatures: -15 °C to 20 °C

Refrigerants used: R22, R134a, R407C, R410 A, C02, It has also been used in many new refrigerants.

Economic life of our country: 15-25 years.

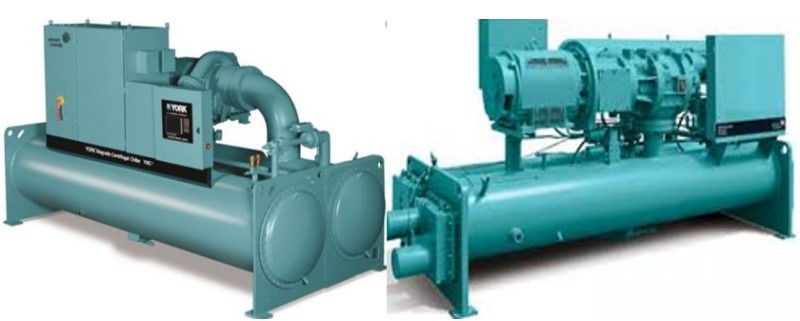

2.1.2.-Water Cooled Cooler Units.

Technicial Specifications.

Condensers are water-cooled devices.

Capacity ranges: Between 50 kW and 10,000 kW.

Compressors: Scroll Type, Piston Type, Screw Type, Centrifugal Type.

Capacity Control: There are gradual and stepless Proportional Type Capacity Control.

Seasonal yield values: Between 300% and 700%.

Leaving Water Temperatures: -15 °C to 20 °C

Refrigerants used: R22, R134a, R407C, R410 A, C02, It has also been used in many new refrigerants.

Economical life in our country: 25-25 years.

2.2.-HEAT PUMP SYSTEMS.

They are systems used in greenhouses where heating and cooling are thought to be done with a single system.

2.2.1.- Air Source Heat Pump Systems.

Technicial Specifications.

Condensers are air-cooled devices.

Cooling Capacity ranges: Between 10 kW and 2000 kW.

Heating Capacity ranges: Between 10 kW and 2000 kW.

Compressors: Scroll Type, Piston Type, Screw Type, Centrifugal Type.

Capacity Control: There are gradual and stepless Proportional Type Capacity Control.

Seasonal yield values: Between 300% and 460%.

Outdoor operating temperature ranges: -30 °C to + 55 °C.

Leaving Water Temperatures: 0 °C to 90 °C

Refrigerants used: R22, R134a, R407C, R410 A, C02, It has also been used in many new refrigerants.

Economic life of our country: 15-25 years.

2.2.2.-Water Source Heat Pump Systems.

Technicial Specifications.

Condensers are water-cooled devices.

They can work as a Sea Source, Lake Source, Ground Source Heat pump.

Cooling Capacity ranges: Between 50 kW and 3,000 kW.

Heating Capacity Range: 50 kW to 3500 kW, The capacity rate can be increased much more with the Cascade system.

Compressors: Scroll Type, Piston Type, Screw Type, Centrifugal Type.

Capacity Control: There are gradual and stepless Proportional Type Capacity Control.

Seasonal yield values: Between 300% and 825%.

Leaving Water Temperatures: 0 °C to 90 °C

Refrigerants used: R22, R134a, R407C, R410 A, C02, It has also been used in many new refrigerants.

They are available in 2-pipe and 4-pipe types.

Available in heat recovery types.

Economical life in our country: 25-25 years.

Since heat pump systems are in the renewable energy class, long-term loans with or without payment can be obtained from many public and private institutions or foreign private credit institutions.

Since heat pump systems are in the renewable energy class, long-term loans with or without payment can be obtained from many public and private institutions or foreign private credit institutions.