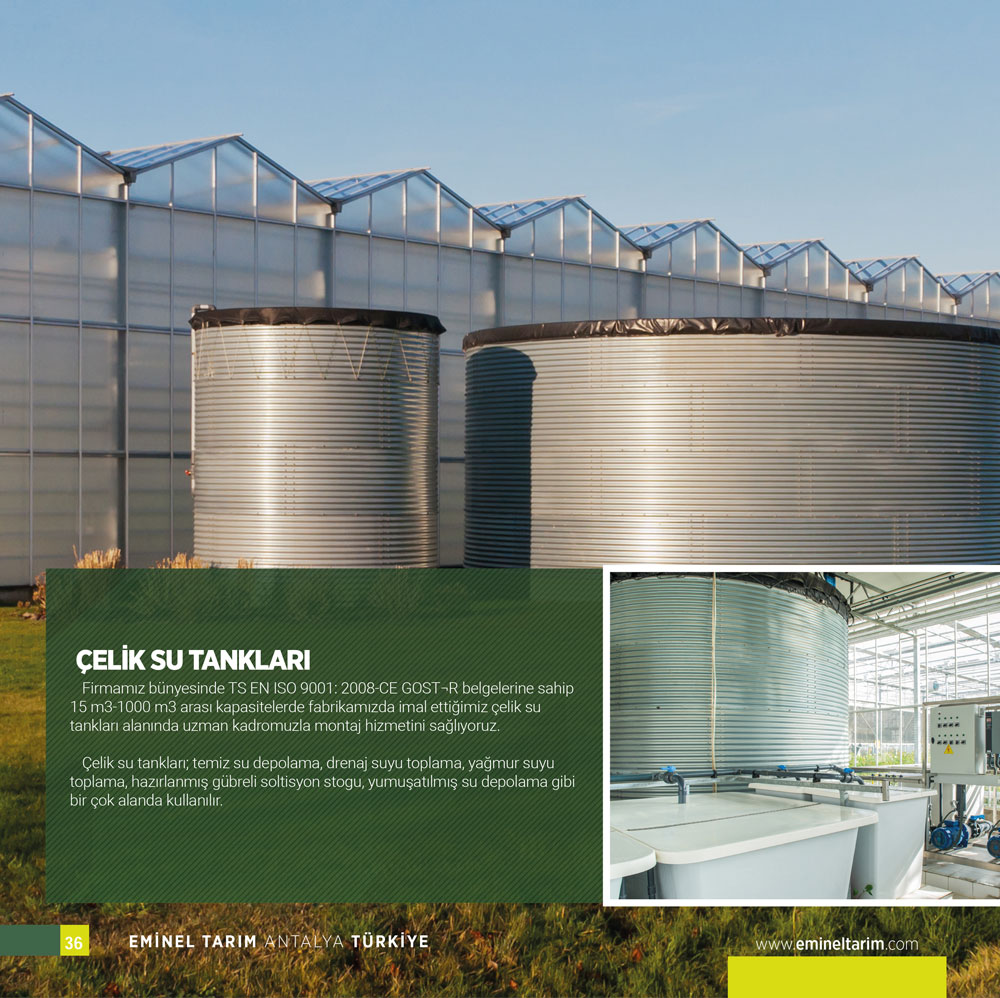

Within our company, we provide assembly service with our expert staff in the field of steel water tanks that we manufacture in our factory with TS EN ISO 9001: 2008-CE GOST ¬R certificates, with capacities between 15 m3-1000 m3.

Steel water tanks; It is used in many areas such as clean water storage, drainage water collection, rain water collection, prepared fertilizer solution stock, softened water storage.

1-SERA BUFFER TANK SYSTEMS.

Buffer Thermal Storage Purpose of Use: Especially when there is insufficient lighting and the CO2 value in the greenhouse falls below 300 ppm during the day, the CO2 discharged from the chimneys of the Heating Boilers is sent into the greenhouse with a special system. For this, when the temperatures inside the greenhouse are high enough during the daytime, the greenhouse Heating circuit is stopped and the Heating boiler starts to heat the water in the Buffer Tank to produce CO2. This stored hot water meets the heating need in the greenhouse when the Heating Boiler does not work later. Therefore, Buffer Depolars not only provide the function of storing heat in greenhouses, but also meet the need for CO2 in the greenhouse.

1.1- GREENHOUSE CO2 ENHANCEMENT SYSTEM:

Plants take CO2 during the day and photosynthesize and give O2 to the environment. At night, they take O2 and give it CO2 to the environment. Therefore, CO2 is a vital gas for plants.

General properties of carbon dioxide

Carbon dioxide; It is a tasteless, colorless, odorless, non-flammable and weak acid gas with the chemical formula of CO2. It is 1.53 times heavier than air. Although it is not toxic, when it is present in the air at the rate of 30%, it has the feature of obstructing the respiratory tract. The amount of carbon dioxide in the atmosphere is about 0.03%. Carbon dioxide production is made in factories from natural underground outlets and chemical methods. Carbon dioxide can be liquefied and solidified at high pressures and temperatures.

Carbon dioxide levels and possible effects for plants CO2 Limit Values (ppm) Possible Effects on Plants

10,000 ppm Plants die.

1200 ppm Plants provide the best growth.

350 ppm Natural value in the air, has no effect on plants.

150 ppm Photosynthesis stops and plants begin to die.

100 ppm Plants die.

The effect of increasing carbon dioxide on plants.

Increasing the amount of CO2 in the growing environment will allow your plant to use the excess water and energy stored in its leaves, and this will result in a drastic increase in growth. The CO2 level in outdoor environments is 300-600 ppm on average. But plants can use more than that. The amount of CO2 in a plant-grown environment can be increased to 800-1500 ppm. This is 3 to 6 times the amount we encounter in outdoor environments. As a result, when the amount of carbon dioxide in the environment is increased, plants grow faster and more. When the amount of CO2 is increased, the growth rate of plants can be increased as high as 100-200%. The genetic structures of plants show different responses to CO2 fertilization.

Although there are differences between the varieties in the studies carried out in this direction in some plants, the average yield increase in plants is around 50-55%.

Young plants have higher optimal CO2 requirements than mature plants. This is because as plants develop, other growth factors become more restrictive. Since the assimilation is at the highest level between 10.00 - 16.00 on sunny days, CO2 fertilization should be done at these times in order to increase the yield of the plants.

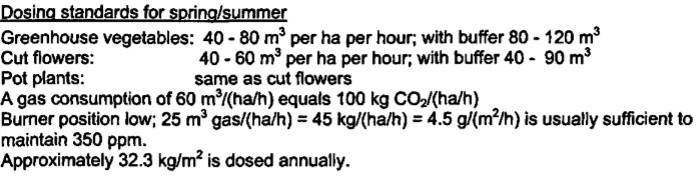

As can be seen in the table above, in order to produce products in greenhouses under suitable conditions, vegetables

40-80 m3 of CO2 per hectare should be taken in production.

80-120 m3 buffer tank should be taken per hectare.

Because up to 100 m3 buffer tank capacity per hectare, the yield increase is very high in greenhouses. After exceeding the 100 m3 capacity, the increase in efficiency slows down and natural gas consumption increases. At the same time, the product increase in kg/m2 is slowing down.

BUFFER TANK TECHNICAL SPECIFICATIONS.

Buffer Tanks are manufactured from ST-37 Steel Sheet Plate.

Design Temperature Maximum: 95 °C

Snow Load. 750 N/m2

Bottom Plate Thickness: 6 mm

Commonly Used Capacities: Between 500 m3 and 5000 m3.

Curb Weight: Between 20.000 Kg and 50,000 Kg.

The thickness of the normal lateral plates: It varies between 5 mm and 10 mm.

Depending on the Capacity and Height, sheet thicknesses vary between 4 mm and 10 mm.

Thicker steel sheets are used for larger capacities.

Wind Load: 35-40 m/s

BUFFER TANK THERMAL INSULATION SYSTEM

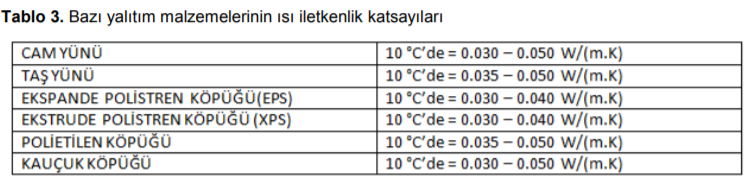

Thermal insulation materials used in Buffer Warehouses can be of various types.

The most used.

Rubber Thermal Insulation Material: 10 - 20 cm

Stone Wool Insulation Material: 10 – 20 cm

Glass Wool Insulation Material: 10 – 20 cm

Their technical specifications are below.

GLASS WOOL

Areas of use: Hot lines, air conditioners, ventilation ducts

Thermal conductivity calculation value: λ<0.05 W/m.K at +10°C

Usage temperature: -50 / 250 °C ( +450 °C without Bakelite) (Also in the range of -200 / +400ºC

Special glass wool products used can also be produced)

Combustion class: A1-A2 class

Vapor diffusion resistance coefficient: μ=1

Thicknesses produced: Plate 3/10 cm, Pipe 25/100 mm

Pore structure: Open pore

ROCK WOOL

Areas of use: Hot lines, air conditioners, ventilation ducts and fire insulation

Thermal conductivity calculation value: λ<0.05 W/m.K at +10°C

Usage temperature: -50 / 750 °C

Combustion class: A1-A2 class

Vapor diffusion resistance coefficient: μ=1

Thicknesses produced: Plate 3/10 cm, Pipe 25/100 mm

Pore structure: Open pore.

ELASTOMERIC RUBBER FOAM

Areas of use: In cold and warm lines, air conditioning and ventilation ducts

Thermal conductivity calculation value: λ<0.05 W/m.K at +10°C

Usage temperature: -70 / 110 °C (produced at -200/+170)

Combustion class: B s3 d0 and B s2 d0

Vapor diffusion resistance coefficient: μ>3000 or μ>7000

Produced thicknesses: Pipe 6/32 mm, Plate 6/50 mm

Pore structure: Closed pore

Buffer tank capacity in greenhouses where vegetables are produced, according to the explanations described above. It is 80-120 m3/ha.