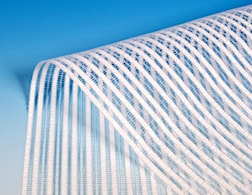

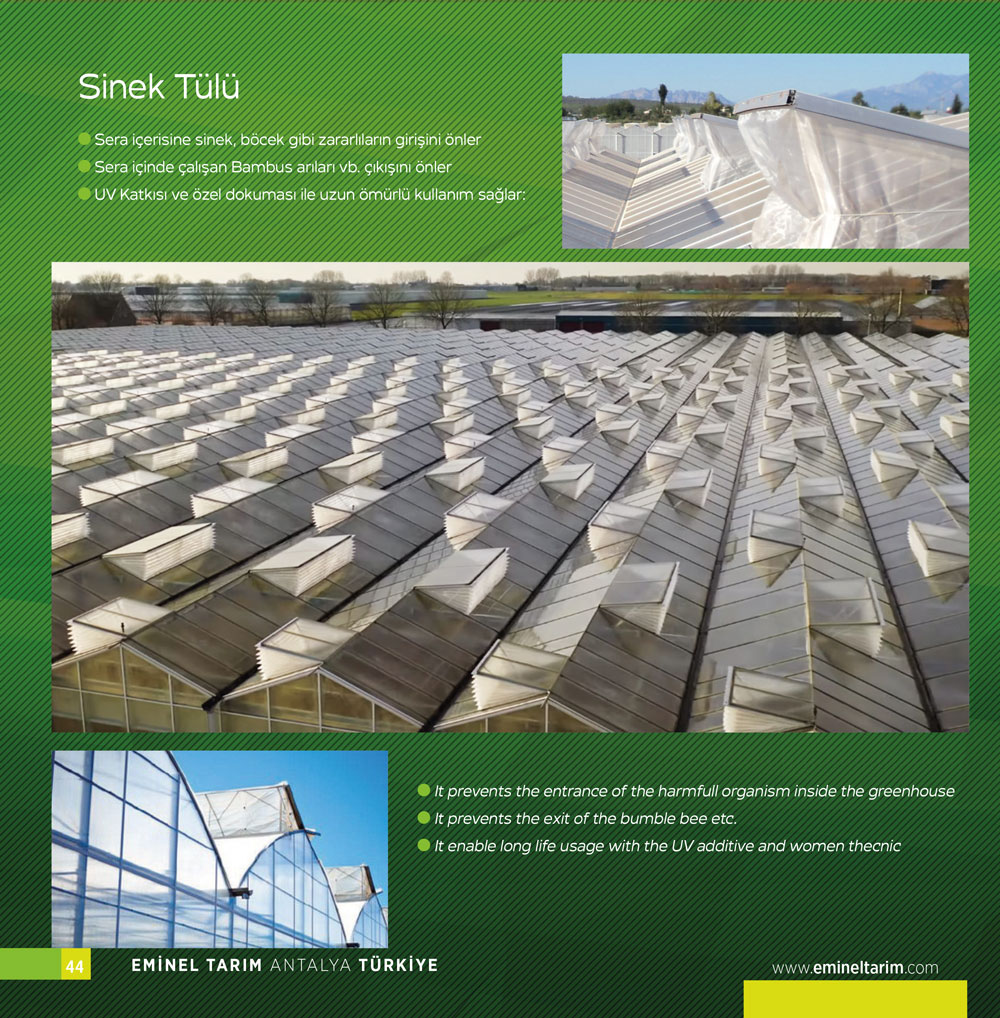

Fly Net Prevents the entry of pests such as flies and insects into the greenhouse. Bambus bees etc. working in the greenhouse. Provides long-lasting use with its UV Additive and special weaving.

Insectnet Fly Net

Many insects cause direct and indirect damage to plants. direct damage; extends from plant sap absorption to leaf damage. The much more serious indirect damage is made certain by the fact that some insects carry viruses that cause reduced production, causing defects and rot until the plant dies. Insects that most commonly affect plants (especially tomatoes); Tuta (absoluta) trialeurodes vaporariorum is commonly known as "White Fly". It carries generic viruses. Bemisia Tabaci and Frankliniella occidentalis carry Tomato Spotted Wilt Virus (TSWV) and Tomato Yellow Leaf Curl Virus (TYLCVA). Chemical and Microbiological control tools are undoubtedly effective in terms of their power to control insects, but before they are killed by the pesticide used in greenhouses, insects pierce the plants and infect the virus. A physical barrier is now used to prevent insects from entering greenhouses. Weaving a Net of eye size that varies according to this protected insect. This type of protection is widely used all over the world, preventing the entry of virus-carrying insects as well as keeping greenhouse pesticides inside to control other harmful insects.

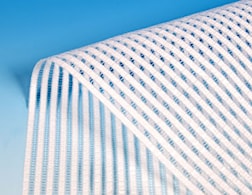

3325BT BIORETE 25 MESH 10 X 8

3341BT BIORETE 40 MESH 16 X 10

3350BT BIORETE 50 MESH 20 X 10

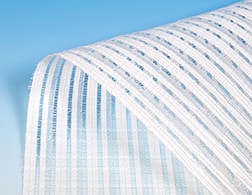

1-Polymers

Agricultural protection nets made by Arrigoni are produced using 1st quality polymers supplied by the most important manufacturers in Europe.

2- Special Mixing System

The material used to provide the bond between HDPE polymer and its additives (UV stabilizer and color) is really very special (gresimetric mixer) the perfect and homogeneous distribution of the said additives in the polymer bulk mixture, instead of ''volume'' or ''simple human applications. It guarantees the 'weight measurement' system by using it as a parameter.

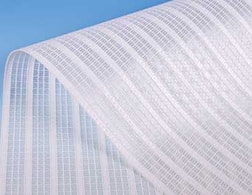

3- Production Process

All the machines available in our production factory (after 2000) are of modern standards and allow the products to have the highest strength and durability.

The production process (turning stage and weaving knitting stage) is carried out by highly qualified operators within the factory, so the factory has high-level production quality and keeps all production processes under direct control.

4-Quality Management System

The company is ISO 9001: 2000 and ISO 14001,2000 system certified. And since 2007, it has been on the list of companies registered with EMAS. Eco – Management and audit plan is a management tool for companies to increase their evaluation, reporting and performance in line with environmentally friendly purposes.

5-Net Identification (Detecting Monofilament)

To ensure that the Arrigoni company produces the net, a special kind of monofilament "producer ID" or "trace" is used in the warp direction within the net. It guarantees the possibility of "optical" (under a special light) and "chemical" tracking.

6.Test Lab

The company has a test laboratory that can test quality, durability and product life with many equipments. 28n net samples are constantly under test.

7.Product Defects Liability

In case of defect or deterioration in the net, the liability of Arrigonine is limited to the change of net only. The change will be made in proportion to the remaining life of the net.

WARRANTY CONDITIONS;

GENERAL PRINCIPLES OF WARRANTY COVERAGE FOR USE AND REPAIR OF NETS

For the most effective and most appropriate use of the Arrigoni nets you have purchased, we recommend that you follow the principles below seriously.

GENERAL PRINCIPLES

Store .Net Rolls horizontally on a soft surface in a shaded, protected area

. Keep 0.5 square meter sample of net with ID tag after installation

.As far as possible avoid contact of nets with other non-polyethylene plastic materials, this will accelerate wear and tear

. Do not expose the nets to the sun open or closed so that they will not stick.

. The storage period of nets should not be longer than 1 year.

. Do not drag the rolls

CONSTRUCTION PREPARATION

Disinfect frames and wooden parts with non-petroleum-based materials.

Strengthen the greenhouse structure (especially the supports and tensioning parts) and replace the faulty parts.

.Do not use PVC profile, we recommend using wood or metal profile instead

.Make sure that the parts of wood and metal in contact with the net are not sharp, cover the corners and protruding parts with polyethylene tape.

.Before the installation of the nets, clean and rinse the greenhouse against rust residue.

.If you are installing unstitched nets together, attach the first net to the sides of the greenhouse, then attach the other to the first and tie it to the sides of the greenhouse. Continue in this manner until the entire greenhouse is closed.

Arrigoni is not liable for damages in case of violation of these principles.

INSTALLING NETS

Greenhouse Cover with Net

Open the packed net and lay it vertically in the grooves, roll the net horizontally to create a longitudinal roll that will allow it to unfold as described

The net is removed to the top of the greenhouse as shown; The net is lifted up by the workers standing at the top of each trough, holding the ends of the ropes attached to the net below, and spread over the top of the greenhouse. This process should be carried out in a coordinated manner.

The net unfolds and spreads at the top of the greenhouse

Connecting the net to the greenhouse is accomplished in three steps; After spreading the net at the top of the greenhouse, the end of the net (transverse) is bent around a beam and nailed to the wooden rails used in the installation of the side curtains. The same actions are repeated on the reverse side, stretching the net (longitudinally)

After the installation of the first net unit is complete, the other unit is removed as described above.

When multiple nets are spread in parallel, they should be tied together with ARRIGONI UV resistant threads.

If heavy wind storms are expected, longitudinal PVC or (30 cm wide) net strings should be pulled with light tension to the net above the gutters.

If any bulges or screws (in glass or polycarbonate greenhouses) come into contact with the net, they should be prevented.

HEAT CURTAIN

Belgian Brand Bonar and Dutch Brand Svensson thermal curtains, floor coverings and other products of these brands are put into service at Eminel Tarım.

BONAR THERMAL SCREEN