Multi-Layer, Common, Thermal or Long-life plastics with excellent mechanical properties that facilitate installation and resist temperature variations throughout the year

Poly-Hort BV & Politiv ltd, overview:

Poly-Hort BV is responsible for sales, service and support.

Polyethylene films produced by Politiv Ltd in Israel and Insect Net .

It is used in Europe, Asia and Oceania.

Politiv Ltd was founded in 1985 and has over 30 years of experience.

innovative mindset. Poly-Hort belongs to the Politiv group.

Polyethylene film is widely used in poly greenhouses, poly tunnels, warehouses, soil disinfection and solarization, mulch film, etc.

Poly-Hort BV & Politiv Ltd Unique Selling Points:

USP's Poly-Hort & Politiv products and organization:

• Quality products

• Production process with modern advanced technology

• Continuous innovation and development of new products

• Products with added value

• Special film development according to customer request

• Flexibility for minimum order (1.5 - 2 tons depending on product type)

• Flexibility for 1.0m - 16m film widths

• option to install a film rewind machine and distribution centre. Machine used to rewind master rolls into smaller rolls according to customer demands

• Customer/distributor support as well as joint support for the end user

• Competitive pricing, right price and quality ratio

• Best payment terms

• Short production and delivery time

• Customer service oriented and support

quality control laboratory

Poly-Hort BV Laboratory and quality control:

Politiv has a quality management system and operates according to the ISO 9001:2008 standard.

• In order to guarantee a high level of product quality, the quality control laboratory meets the samples during production and the required quality requirements 24/7. Every movie order sample produced

kept in the archive for at least 4 years.

Polyethylene film as greenhouse cover:

Poly-Hort BV Polyethylene film as greenhouse cover can be divided into the following parts:

• Polyethylene film protecting the product against weather conditions:

wind, rain, snow etc. effects

• Polyethylene film that helps control the microclimate:

greenhouses such as light, temperature and humidity

• Additional Value Smart Polyethylene Film

The main purpose of the poly greenhouse/tunnel:

The main purpose of the Poly-Hort BV Poly greenhouse:

• Creating a controlled and consistent microclimate for light quality,

To control the temperature and humidity inside the greenhouse independent of the outside climatic conditions. A controlled climate means higher yields.

• Protection of the product.

• Crop improvement, quality and higher yield.

• Development and extension of the growing season.

Effect on greenhouse climate by using PE film as greenhouse cover:

• Light: Controls the upper light percentage and light quality.

• Temperature: to influence the temperature during the day and night

• UV-radiation: to control the entered Ultra Violet radiation

Greenhouse Film features:

Greenhouse film can be provided with the following features:

• High level of mechanical properties

• Light transmission (diffuse or direct)

• UV stability (determines the durability of the film)

• Thermicity (film to minimize heat loss in the greenhouse)

• Anti-condensation / ”anti-drip” features

• Anti-fog (anti-mist)

• Anti-Virus (anti-virus)

•Anti-Dust (anti-dust)

High level mechanical properties:

The film must withstand high loads such as wind, rain, snow, hail, and extremely high temperatures, cables and ropes, etc.

Standard Polyethylene films are not resistant to all these climatic effects and must be adapted to:

For adding LLDPE (C-4 and C-6) additives

(LLDPE = Linear Low Density Polyethylene, C4 = Butene, C6 = Hexene)

2. To add Metallocene PE

3. Enable Technology (Enable™ Metallocene polyethylene (mPE) resins)

It was introduced in 2008, almost all films are based on this material. Most advanced Polymer on the market and only 1 manufacturer (Exon Mobile)

Light transmission: diffusion and direct light:

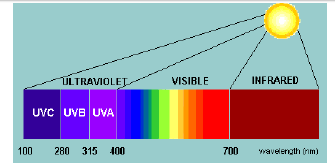

UV-range sunlight

UV range: 100 - 400nm, can be divided into 3 wavelength ranges:

- UV-C: short wave 100-280nm: this radiation will be absorbed by the ozone layer.

- UV-B: medium wave 280-315 nm: UV clear films allow 85% of this radiation to pass. Glass and standard films almost do not allow this range to pass.

-UV-A: long wave 315-400nm: UV-clear films allow 85% of this radiation to pass. Glass and standard films almost do not allow this range to pass.

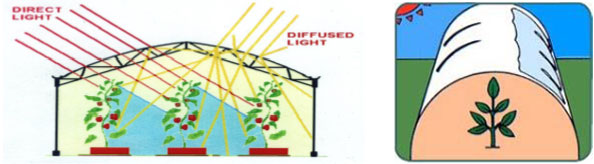

Light transmission: diffusion and direct light: Diffusion light

Using mineral fillers in the film, the light is refracted and dispersed in different directions.

The transparency of the film is not a criterion of light transmittance.

Diffused light is very important for the development of the plant.

Diffused light reduces shadow so the plant can receive more light for PAR than outside light spectrum light.

More photosynthesis takes place for the upper leaves and lower leaves.

UV stability:

UV-stabilizers

We use UV stabilizers to protect the film. These are contributions to the movie.

In the production process to ensure the durability of the film.

Disruption of the film

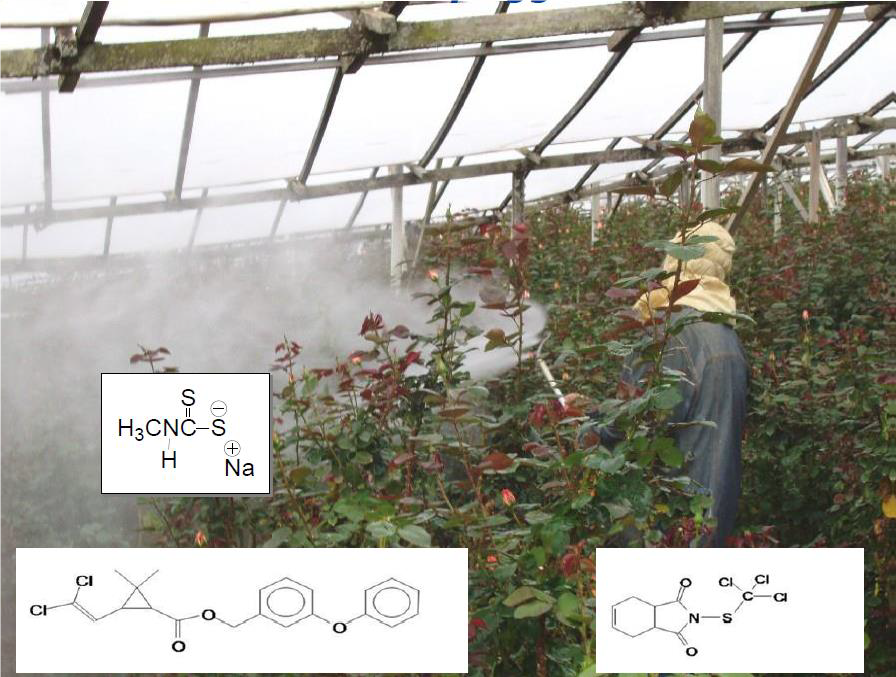

Aggressive agrochemicals such as Sulfur (S) and especially Chlorine (Cl),

Standard UV stabilizers result in rapid film degradation (sometimes already

a few months).

Film Deterioration Signs

- Due to the loss of strong mechanical properties, the film is torn and easily broken.

- Decreased light transmission, the film becomes opaque.

UV stability:

Cause of film degradation:

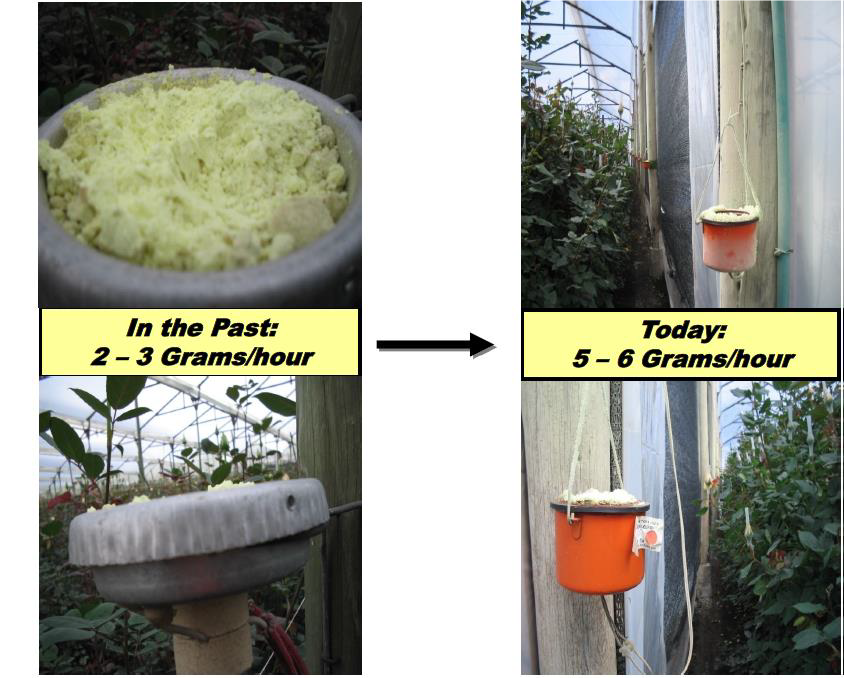

• Growers use sulfur (cheap material, organic) to fight diseases such as mold, especially in the production of strawberries and roses abroad.

• Use of Growers Chlorine sprays (to prevent disease) as disinfection after each crop change.

• Chemical fertilization: using S and Cl-based substances

• Adjustments in the use of pesticides used by growers (legislation)

UV stability:

Cause of film degradation:

• Growers use sulfur (cheap material, organic) to fight diseases such as mold, especially in the production of strawberries and roses abroad.

• Use of Growers Chlorine sprays (to prevent disease) as disinfection after each crop change.

• Chemical fertilization: using S and Cl-based substances

• Adjustments in the use of pesticides used by growers (legislation)

UV stability: film degradation by other factors

It is to prevent the film from the greenhouse from deteriorating and being damaged. The following points should be noted:

• Broken "poly lock" profiles should be replaced.

• Care must be taken to avoid sharp edges that may come into contact with the film to prevent damage to the film.

• All (black) metal or wooden parts must be painted with water-based white paint.

• rusty parts of the greenhouse structure should be replaced so that the film does not deteriorate,

• Use of film in impregnated wooden structures (Halogens),

May cause deterioration as UV-stabilizers are affected

• Preferably all steel structural parts need to be galvanized

Anti-condensation / anti-drip properties: (ANTI-MIST)

Anti-condensation / anti-drip film

Anti-condensation / anti-drip film

Anti-fog properties: (ANTI-MIST)

In some parts of the world there are large variations in temperature during the day, and

night temperature, the formation of fog in the morning may appear in the greenhouse.

The anti-fog additive films the fog and the anti-condensation fog flows into the gutters as a layer of water.

It can have a negative effect on the anti-condensate.

Only in the right percentage and in the right combination the anti-fog and anti-dust work correctly. Otherwise, the anti-condensation function will be lost.

Value-added smart film:

Value-added smart film:

• Film with special anti-dust properties

• Film with cooling effect (Smart aluminum)

• High emissivity film, high light transmittance, high thermicity and high mechanical resistance. (Diamond 15 movie)

Anti-dust film: (ANTI-DUST)

This movie was developed according to a new technology and concept .

No anti-static attachments will be used, which will disappear after a short time.

The anti-dust additive will remain active for the lifetime of the film.

The anti-dust additive makes the film surface smooth.

This option is often used for poly tunnels in outer layers to get rid of dust and dirt.

The result is a higher light transmission. In addition, a smooth film surface

The film is easier to clean.

Film with heat reduction properties

In countries with long sun hours, the temperature in the greenhouse may be too high, thus stressing the plants.

The following measures can be taken to prevent high temperatures in the greenhouse:

• Shadow nets over the film

• Providing the film with “White Wash”

• Milky film with 25% shadow effect (aluminum)

Aluminum film (heat reduction feature)

The film contains a special aluminum pigment

Reflects most of the NIR light (near infrared)

(responsible for heat development)

PAR - light (photosynthetically active radiation).

Shade (PAR light reflection) ranges from 15% to 15%.

25% depending on geographic area and product.

By reducing the NIR radiation (near infrared), the temperature will drop in the greenhouse.

Diamond 15 high diffusion film

high light transmittance and high thermicity

Diamond 15 is a specially developed film with high light transmittance, high light diffusion, high light.

thermality and high mechanical strength.

When the light touches the film, the light can pass through the film directly.

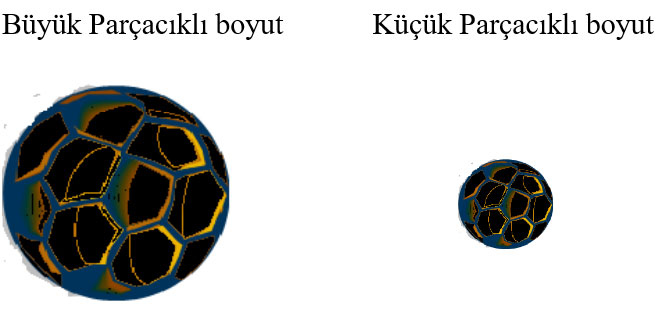

This depends on the composition and particle size in the film.

Light is reflected and is a problem for light transmission. Transmission percentage

depends on the reflection index and the particle size.

A smaller particle size transmits less reflection and more light.

Special Movies:

Special movies:

• Anti-virus film

• Anti-tarnish film

• UV clear or Nectarine film

Special Movies: Anti-Blackout

• Anti-tarnish film

For some rose varieties, UV light can cause hyper-pigmentation,

spots (petal blackening) on flower petals will appear dark.

By blocking the UV range up to a wavelength of 380-390nm, it strongly reduces the presence of dark spots (darkening) on roses.

Special Films: Nectarine or UV clear film

The “UV-on” film passes through unfiltered (reaching the earth's surface) UV radiation.

To open the UV range from at least 320nm, it is necessary to develop bicolor roses, nectarines, red leaf lettuce Anthocyane pigments (red).

Anthocyan pigment needs UV light to give color. Anthocyane gives its purple color to some.

lettuce varieties and eggplant.

Film with a UV filter causes problems with coloring for these products.

Therefore, a UV film must be used.

UV Blocking Film

UV Clear Film

Movie genre selection:

The choice of film genre depends on the following factors:

- Product type

- Percentage of light transmission

- Percentage of scattered light

- Thermal percentage

- Is it the growing season, all year round, or only in summer or winter?

- How many seasons / years should the movie run?

- Is there an anti-condensation / drip film?

- Dustless film?

- Anti-fog film?

- Anti virus movie?

- Film with clear UV?

-Film with EVA for cold climates.

- Geographical location of the project in relation to UV radiation, temperature, number of sun hours. In Northern Europe, for example, there is less UV radiation.

Southern Europe. ,

- Type of greenhouse structure, does the greenhouse cover consist of two layers or a single layer?

- What width and thickness of the film is needed?

- Are chemicals such as sulfur and chlorine used in the greenhouse?

Greenhouse and tunnel constructions