Polycarbonate Coating

Durable, Efficient, and Long-Lasting Solution

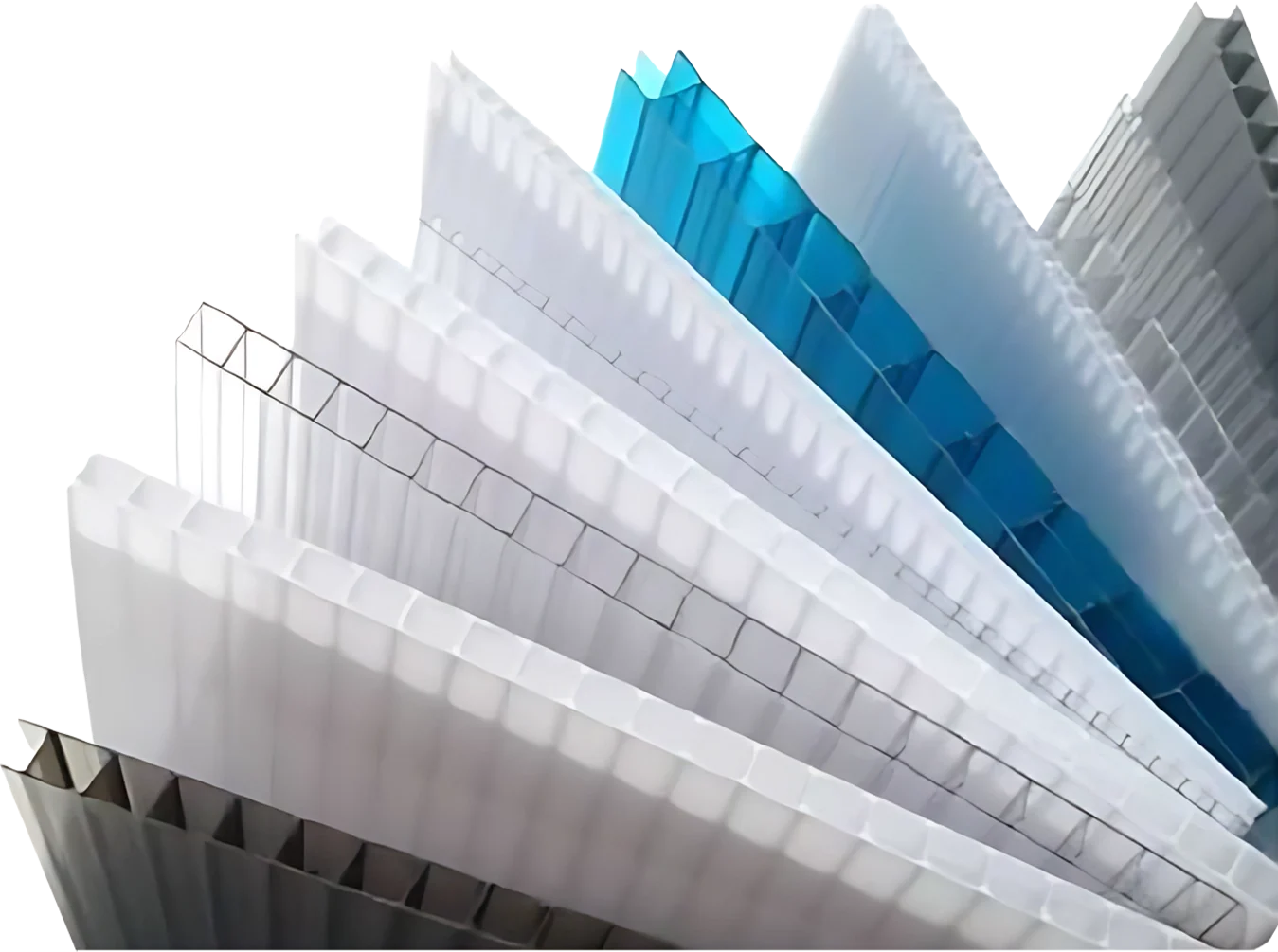

Polycarbonate sheets stand out in modern greenhouse applications with excellent light transmission, high impact resistance, and superior insulation properties. Thanks to their durability in both hot and cold weather conditions, they offer year-round efficient agriculture.

UV Resistance: Filters harmful effects of sunlight.

High Thermal Insulation: Reduces day-night temperature difference with IR additive.

Light Diffusion: Scatters sunlight to prevent leaf burn.

High Impact Resistance: Much stronger and lighter than glass.

Suitable for Cold and Hot Bending: Easily moldable and practical to apply.

Long Lifespan: Excellent resistance to outdoor weather conditions.

Standard Sizes and Thicknesses:

- Size: 210 x 600 cm

- Thickness Options: 4 mm, 6 mm, 8 mm, 10 mm, 16 mm

- Structure Type: Corrugated (multi-wall) or solid (flat)

High Efficiency with Polycarbonate Greenhouses:

Polycarbonate greenhouses optimize plant growth by ensuring more balanced light distribution. Thanks to their heat retention properties, they minimize the risk of frost and dew during winter and prevent plant stress.

They offer early planting and late harvest opportunities, especially in vegetable and fruit production. They are also widely used in hobby gardens, seedling cultivation, and flower production.

Areas of Use:

Greenhouses (wall and roof structures)

Hobby gardens

Roof lights and ceiling lighting

Veranda and terrace coverings

Pool cover systems

Bus stops, sound barriers

Entrance canopies and factory windows

Sports halls, overpasses, parking lots

Difference Between Glass and Polycarbonate:

| Material | Durability | Weight (10 mm) | Thermal Insulation | Formability |

|---|---|---|---|---|

| Flat Glass | Fragile | 25 kg/m² | Low | Poor |

| Solid Polycarbonate | Very Durable | 12 kg/m² | Medium | High |

| Corrugated Polycarbonate | Very Durable | 1.7 kg/m² | High | High |

Practical Use – 4-Season Greenhouse Experience

Whether you want to grow your own vegetable seedlings or enjoy fresh greens in midwinter, it's all possible with polycarbonate greenhouses!

- February – First lettuce crops are planted.

- March-April – Tomato, cucumber, and eggplant seedlings are cultivated.

- October – Winter lettuces, parsley, celery, and other greens are transferred to the greenhouse.

- Winter – Plants are protected from frost and dew; production continues.

With their durability, flexibility, and energy-saving properties, polycarbonate greenhouse systems are indispensable for modern agriculture.

Contact us for more information and product supply.

TECHNICAL SPECIFICATIONS

| Specifications | Value | Test Method |

|---|---|---|

| Density (g/cm³) | 1.2 | ISO 1183 |

| Water Absorption (%) | 0.35 | ISO 62 |

| Tensile Strength (MPa) | 2300 | ISO 527 |

| Operating Temperature (°C) | -40/+120 | |

| Fire Classification | B-s1d0 | EN 13501 |

| Hail Resistance (10-16-20-25-32 mm) | PASSED | Internal Test Method |

| Vicat Softening Temperature (°C) | 145 | ISO 306 |

|

PRODUCT FEATURES |

|||||||||

|---|---|---|---|---|---|---|---|---|---|

| Thickness (mm) | 4 | 6 | 8 | 10 | 16 | 16 | 20 | 25 | 32 |

| Number of Walls | 2 | 3 | 7 | 7 | 9 | 9 | |||

| Width (mm) | 2100 | ||||||||

| Length (mm) | 6000 / 12000 | ||||||||

| Weight (g/m²) | 700-850 | 950-1300 | 1200-1500 | 1300-1600 | 2500 | 2500-2650 | 3000 | 3400 | 3800 |

| U Value (W/m²K) | 3.77* | 3.33* | 3.04* | 2.83* | 2.10* | 1.86* | 1.65* | 1.35* | 1.18* |

| Min. Cold Bending Radius (mm) | 600 | 900 | 1200 | 1500 | 2800 | 2400 | 3000 | 3750 | 4800 |

| Thermal Expansion Coefficient | 6.7 x 10-5 m/m·°C | ||||||||

| Sound Insulation (dB) | 12 | 14 | 15 | 16 | 18 | 17 | 19 | 19 | 20 |

| Fire Classification (EN 13501-1) | B-s1, d0 | ||||||||

|

LIGHT TRANSMISSION % |

|||||||||

|---|---|---|---|---|---|---|---|---|---|

| Clear | 79 | 75 | 76 | 75 | 73 | 53 | 49 | 45 | 40 |

| White | 20 | 18 | 14 | 10 | 4.8 | - | - | - | - |

| White Diff. | - | 51 | 50 | 60 | 36 | 28/38 | 28 | 26 | 11 |

| Bronze | 30 | 1/23 | 15/28 | 15/24 | 18 | 20 | - | - | - |

| Blue | 38 | 17.5/35 | 15/28 | 15/32 | 19 | - | - | - | - |

| Green | 30 | 13.5/27 | 13.5/24 | 22 | 14.5 | 14.5 | - | - | - |