Greenhouse Heating Systems

Greenhouse Heating Systems

One of the most critical components of modern greenhouse farming is ensuring optimal climate conditions for plant growth. At the forefront of these conditions is an effective heating system. At Eminel Agriculture, we design and implement the most efficient and sustainable heating systems for your greenhouse projects.

Our Solutions for Heating Systems

Greenhouse heating systems are designed based on the region's climate characteristics, the type of plants to be grown, and available energy sources. In regions with geothermal resources, our experienced engineering team conducts well tests, characteristic analyses, and flow-temperature measurements. Based on this data, the most suitable system is selected, and tailored solutions are provided to the investor.

In areas without geothermal resources, natural gas or solid fuel boiler systems are preferred. During the design process, greenhouses are divided into equal zones, and systems such as floor rail heating, under-gutter heating, crop heating, side heating, ceiling heating, and seedling bench heating are installed. Separate circuits are created for each sector, and heat distribution is maximized with three-way valves and circulation pumps.

Additionally, automatic control systems continuously monitor temperature and humidity levels inside the greenhouse, automatically activating the system to maintain desired values.

Heating Based on Climate Conditions

For optimal plant growth, the ideal greenhouse temperature should be between 15-26 °C, with a relative humidity of 60-80%. The CO level is typically maintained between 300–1200 ppm. Deviations below or above these values negatively affect plant health, yield, and quality. Especially during winter, nighttime temperatures should be stabilized at 13-16 °C. Therefore, greenhouse heating systems must be planned to maintain a consistent indoor environment year-round.

Geothermal Heating Systems

Geothermal resources offer an economical and environmentally friendly solution for greenhouse heating. In regions with sufficient thermal water temperature and flow rate, this system significantly reduces operating costs. However, efficient use of resources is critical. Unplanned or excessive consumption can shorten the resource's lifespan and create environmental impacts.

A thermal water temperature of 60–70 °C is ideal for optimal efficiency. However, temperatures below 50 °C require longer piping systems for heat transfer, increasing initial installation costs.

The chemical composition of the resource, cost per cubic meter, return temperature, and flow rate are critical factors considered in system design.

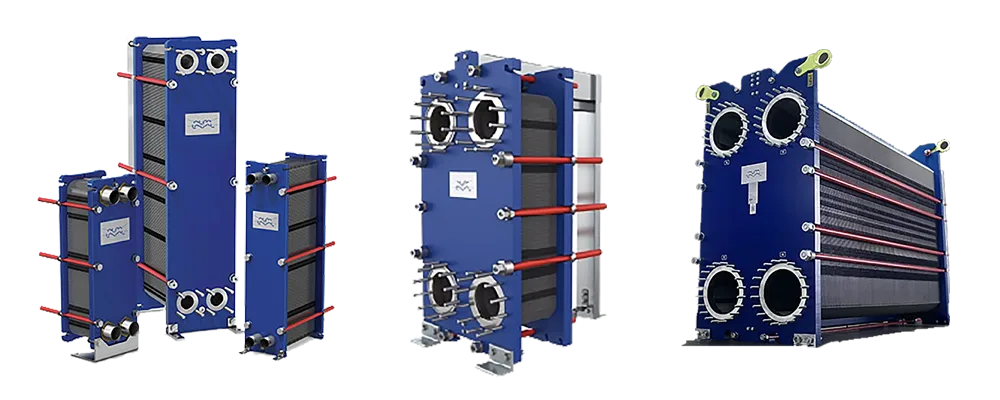

Plate Heat Exchangers

Titanium alloy plates

Stainless steel plates

Heat exchangers transfer heat from geothermal water to system water safely and efficiently. Their capacity typically ranges between 500 kW and 10,000 kW.

Energy Options for Heating Systems

Selecting the right heating system is critical for sustainable and efficient greenhouse production. At Eminel Agriculture, we offer heating solutions with different fuel types based on the region's energy infrastructure and project requirements.

Coal-Fired Boiler Heating Systems

Coal, a widely available and accessible energy source in our country, is preferred in some projects. Domestic lignite coal has an energy value of 4,500–5,000 kcal/kg and a combustion efficiency of 60–65%. However, while coal boilers have low initial investment costs, their operating and maintenance costs are high.

Natural Gas Heating Systems

One of the most preferred systems in modern greenhouse projects. Natural gas stands out with high combustion efficiency, low maintenance requirements, and easy automation integration.

- Provides 85–90% combustion efficiency.

- Has low initial investment and operating costs.

- Fully compatible with automatic control systems.

- Has an economic lifespan of 15–20 years.

- Operates reliably and uninterruptedly with city grid connection.

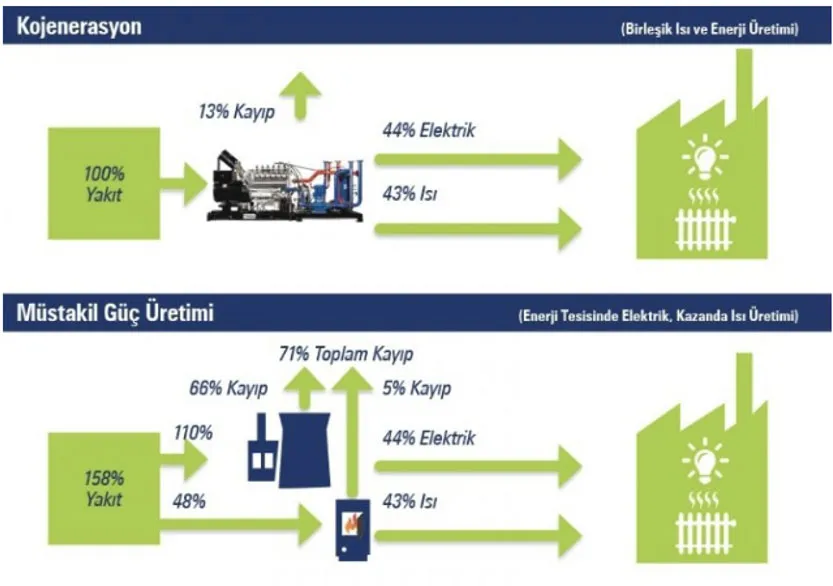

Cogeneration System (CHP – Combined Heat and Power)

Cogeneration systems provide a highly efficient, integrated energy solution by producing both heat and electricity. These systems are particularly advantageous for large-scale greenhouse operations.

Advantages:

- Can produce hot water, steam, hot gas, or cold water alongside electricity.

- Operates with alternative fuels such as natural gas, biogas, or landfill gas.

- Consumption of electricity at the production site eliminates transmission losses.

- Unaffected by grid fluctuations; can switch to the grid during system failures.

- Significantly reduces CO emissions, offering an environmentally friendly solution.

- Energy efficiency is much higher than traditional systems.

- Utilizes waste heat to minimize unit energy costs.

- Provides independent and reliable infrastructure through local energy production.

Application Areas:

- Industrial greenhouses

- Large-scale greenhouse complexes

- Agricultural production facilities with high energy demands

General Assessment

When selecting heating systems, the following are considered:

- Regional availability of energy sources

- Economic and environmental impacts of fuel types

- Installation and automation integration capabilities

- Long-term operating costs

- Climate requirements based on plant type

At Eminel Agriculture, we design the most suitable heating system for each project with tailored technical analyses and engineering calculations, perform installations, and provide support for long-term efficient operation.

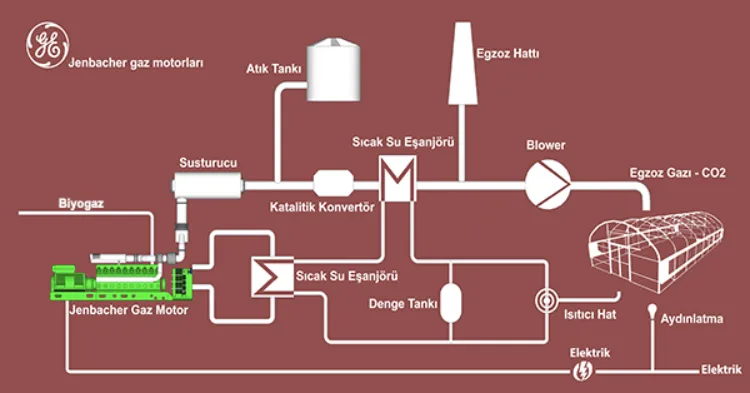

Benefits of Cogeneration in Greenhouses

Cogeneration (CHP – Combined Heat and Power) systems are a highly advantageous solution for modern greenhouse farming, enhancing energy efficiency, environmental sustainability, and production yield. With natural gas-powered gas engines, both electricity and heat are produced simultaneously, and the resulting high-quality carbon dioxide (CO) is utilized for plant growth, integrating into the production process.

Up to 95% Energy Efficiency

Cogeneration systems achieve energy production efficiency of up to 95%. This high efficiency ensures maximum fuel utilization, conserving energy resources and reducing operating costs to increase profitability.

Electricity Production and Sales: Electricity generated by cogeneration systems can be used within the greenhouse or sold to the national grid. Sales during high-demand periods create an additional revenue stream for greenhouse operations.

Effective Use of CO and Waste Heat

In cogeneration systems, the exhaust gas produced from natural gas combustion is rich in CO. After purification through special catalytic converters, this gas can be used within the greenhouse. Similarly, the waste heat generated is efficiently utilized for greenhouse heating.

- Exhaust gas is processed through special filtration and cooling systems, reduced to approximately 55°C, and released into the greenhouse.

- Gas composition is continuously monitored during this process to maintain safe and efficient CO levels for plants.

Carbon Dioxide Enrichment for Plant Growth

Plants use CO as a carbon source during photosynthesis to grow. In natural atmospheric conditions, CO levels are around 350 ppm. However, for optimal plant development, this level can be increased to 700 ppm.

- CO-enriched environments, combined with artificial lighting systems, enhance photosynthesis rates, accelerating plant growth.

- This results in significant advantages such as increased harvest frequency, improved product quality, and higher yield per unit area.

- Approximately 0.2 kg of CO is released per 1 kWh of electricity production, creating an economical and natural carbon fertilization opportunity in greenhouses.

Energy Integration

Energy obtained from gas engine cogeneration systems can be used in greenhouses in multiple ways:

- Electrical energy: Powers artificial lighting systems or can be sold to the grid.

- Thermal energy: Meets greenhouse climate control and hot water needs.

- CO gas: Directly benefits plant development.

Environmentally Friendly and Economical Investment

Cogeneration systems are an ideal solution for both energy savings and environmental sensitivity:

Thanks to all these advantages, cogeneration systems stand out as the future model of greenhouse farming and are becoming increasingly widespread worldwide.

Trigeneration System

Trigeneration is an integrated energy solution that adds cooling functionality to cogeneration systems, producing electricity, heat, and cooling energy simultaneously. It is ideal for maintaining a consistent indoor temperature year-round, especially in large areas with climate control needs.

Trigeneration provides superior benefits in modern greenhouses in terms of climate control continuity, plant yield, energy efficiency, and environmental sustainability.

In-Greenhouse Heating Systems

In-greenhouse heating systems are specifically designed to ensure uniform temperature distribution throughout the greenhouse and support plant growth based on climate conditions. Below are the most common applications:

Tichelmann Method (Main Distribution Line)

The Tichelmann principle is a piping system designed based on equal pressure drop. It ensures equal flow distribution in each line without the need for additional control valves. It is one of the most efficient distribution methods, providing natural flow balancing.

Rail Heating System

Heating pipes are laid horizontally on the ground in 12 rows per tunnel.

Pipes used: Q51 – 2.5 mm black steel pipes placed on S-pot supports.

The most commonly used heating system in greenhouses.

Under-Gutter Heating System

Applied in addition to rail heating systems in cold climates.

Pipes are placed horizontally under plant beds.

12 rows are laid per tunnel.

Pipes used: Q51 – 2.0 mm black steel pipes.

Crop Heating System

Heating pipes are laid in 6 or 12 rows along the tunnel within the greenhouse.

Pipes are suspended from the ground using special hanger systems.

Pipes used: Q38 – 2.0 mm black steel pipes.

Provides heating close to the plant root zone, directly supporting growth.

Snow Melting System

Used in regions with heavy snowfall and extreme cold.

Typically applied as under-gutter heating.

Pipes used: Q51 – 2.0 mm.

Protects the greenhouse's structural safety by reducing snow load.

Perimeter (Side) Heating System

Applied by laying pipes parallel to the greenhouse walls.

Pipes used: Q51 – 2.0 mm.

Designed with 4, 6, or 8 rows.

Reduces heat loss and enhances indoor temperature uniformity.

Complementary Products Used in Greenhouse Heating Systems

The long-term, reliable, and efficient operation of greenhouse climate control systems depends not only on the main heating systems but also on the proper selection and application of complementary products. Below are the commonly used complementary equipment in greenhouse heating systems:

Rubber Hoses

Purpose: Used to connect the main Tichelmann loop to secondary lines.

Hose Diameter: Q27

Average Length: Approximately 3 meters per row

Advantage: Its flexible structure allows easy application at connection points.

Console and Hanger Systems

Purpose: Carrying and securing main and lateral heating pipes.

Types: T-hanger system, U-hanger system, hanger rings

Advantage: Ensures secure pipe installation with high load-bearing capacity.

Tee – Coupling and Clamp

Purpose: Facilitates transition and connection from main lines to secondary lines.

Curved Tee: Particularly preferred in crop heating systems.

Advantage: Provides leak-proof and robust connections.

Spot Supports

Purpose: Used to carry pipes off the ground in rail and under-gutter heating systems.

Advantage: Provides stable ground installation and long-term durability.

Greenhouse Heating and Geothermal Infrastructure Pipes

Purpose: Transfer of energy between heating and cooling systems.

Pipe Types: Black welded pipes, industrial pipes, and insulated geothermal pipes

Diameter Range: Q38 – Q350

Wall Thickness: 2.0 mm – 5 mm

Advantage: High heat resistance and long-term durability.

Automatic Control Valves

Function: Manages energy within the greenhouse and ensures temperature stability.

Control Type: On-off or proportional control

Diameter Range: DN32 – DN250

Valve Types: 2-way and 3-way motorized valves

Lifespan: 15 years

Advantage: Maximum energy efficiency and low operating costs

Heating Pumps

Function: Circulates hot water within the greenhouse.

Pump Type: Inline (pipe type)

Flow Rate Range: 0 – 500 m³/h

Head Pressure: 0 – 100 mSS

Efficiency: 50% – 80%

Control: Fixed speed or inverter-controlled

Lifespan: Average 15–18 years

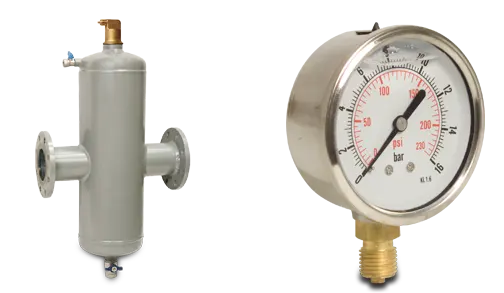

Shut-Off and Control Components

This group consists of components that ensure the safety of the greenhouse heating system during service, maintenance, and operation:

Components: Ball valve, butterfly valve, strainer, check valve, air separator, sediment separator, air vent, pressure gauge, thermometer, flow meter

Functions Provided:

- Flow direction and shut-off

- Ease of maintenance and service

- Filtration of foreign substances

- System balancing through air release

- Temperature and pressure monitoring

Flange – Bolt – Nut – Washer Group

Purpose: Used at connection and joining points

Advantage: Provides high leak-tightness and robust mechanical connections.

Thanks to these complementary systems, greenhouse heating projects become longer-lasting, require less maintenance, and are more energy-efficient. Each component plays a significant role in creating a controlled microclimate within the greenhouse and increasing agricultural productivity.